√ダウンロード one piece flow vs batch production 319955-One piece flow vs batch production

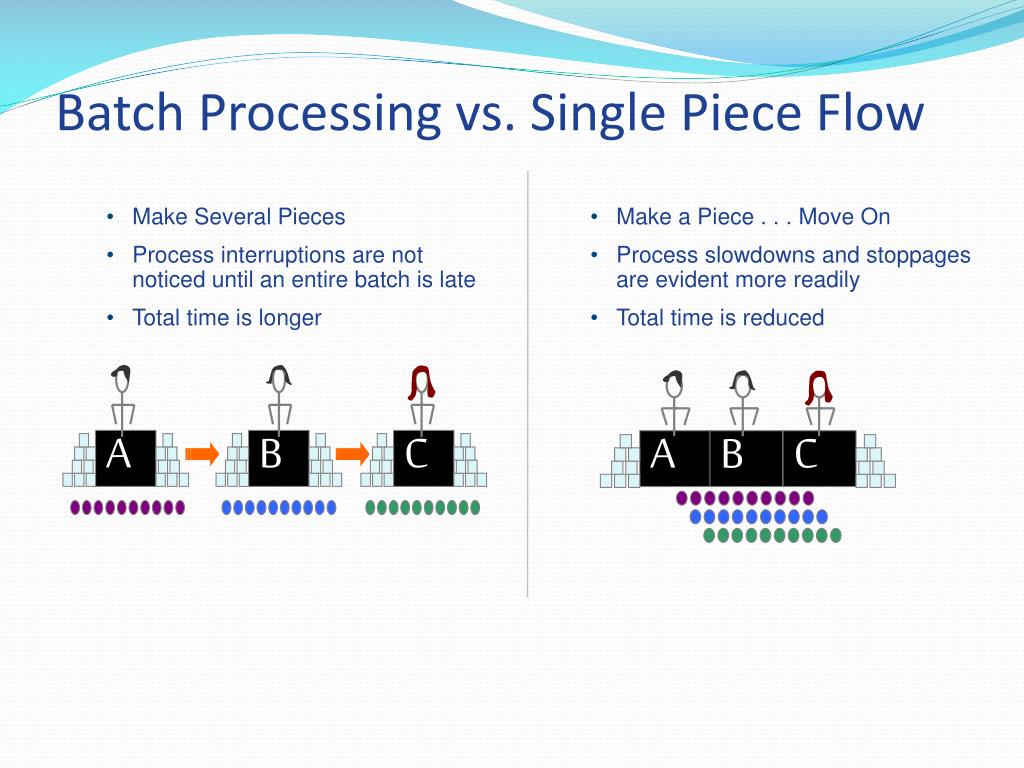

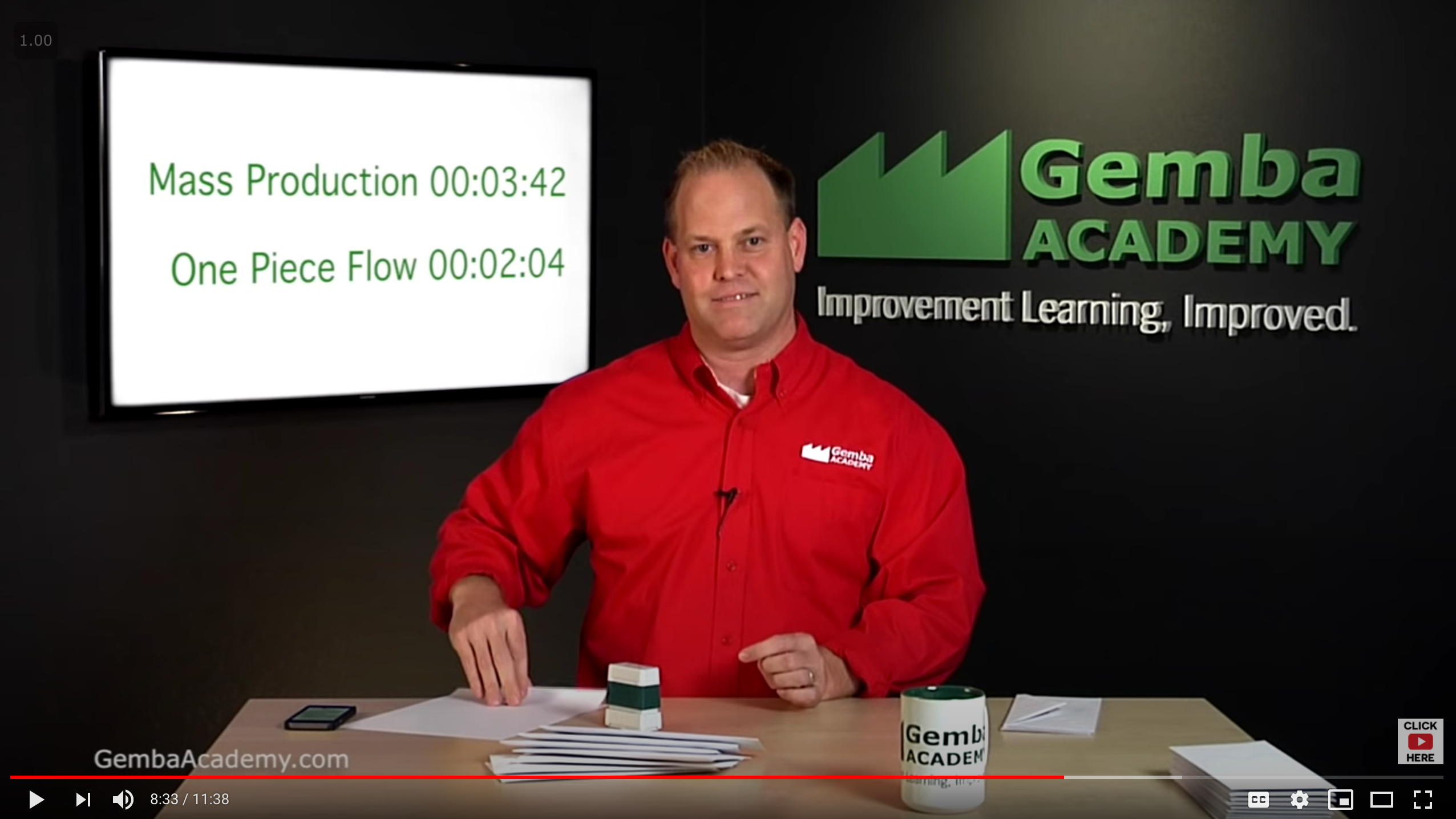

This video talks about the One piece flow sometimes referred to as "singlepiece flow" or "continuous flow," and how is it different from Batch productionWe help you to implement or improve Quality Management Systems based on international standards ISO 9001 ISO/TS ISO ISO/TS Supplier Evaluation & Management Supplier Auditing First Article Approval Internal Auditing Quality Training CE Marking For example, in the video below we can see some proof of how much faster one piece flow can be than batch processing However, the argument can be made that the process could be sped up even further by separating the work into different stations, having one person fold the boxes, one put the stickers on the boards, and so on

Batch Vs One Piece Flow Manufacturing Treston

One piece flow vs batch production

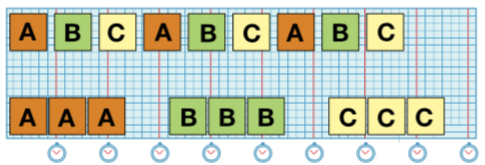

One piece flow vs batch production-OnePiece Flow vs Batching A Guide to Understanding How Continuous Flow Maximizes Productivity and Customer Value provides concrete arguments as to why batching, while sometimes necessary, is never the most efficient solution for most processes It explains why flow, especially onepiece flow or continuous flow, should always be your ultimate#Simulation of one piece flow vs batch production basics for starters #lean #kaizen #onepieceflow #flow #ci #cip #visual #continuousimprovement by Liked by Avery Chua (蔡少龙) To all the super mums out there Thank you for being CEO of the family and taking care of everyone

Comparison The Batch Production And One Piece Flow Activity Download Table

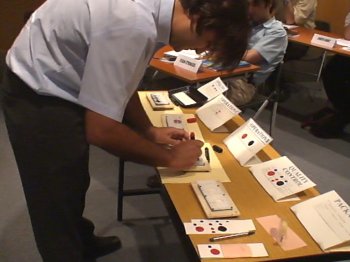

Single Piece Flow vs Batch Production Most lean games and simulations run in phases, contrasting the traditional batch production techniques with lean single piece flow processes Whether you use paper airplanes or pennies, these games are perfect for really showing people the differences When you experience single piece flow in a hands on activity, it's easier to I think the main benefit I noticed (and everyone sees) is related to how much of a groove I fell in when doing the one piece flow portion Working in batch mode is boring and uninspiring However, working in a one piece flow manner is far more fulfilling and it's much easier to get into a groove so to speakWhat's the difference between running in batch mode, or running one piece at a time?

Peanut Butter Sandwiches, OnePiece Flow There are two ways to build sandwiches — the BatchandQueue method or the OnePiece Flow method BatchandQueue To build sandwiches the BatchandQueue style I would take 3 pieces of bread (3 lunches to make) and place peanut butter on it Single Piece Flow vs Batch Production Stuffing Envelopes When you have only one person in a work cell, what are the benefits of single piece flow?Http//GembaAcademycom In this video Ron Pereira puts one piece flow up against mass or lot production in a fun, easy to duplicate, envelope stuffing simu

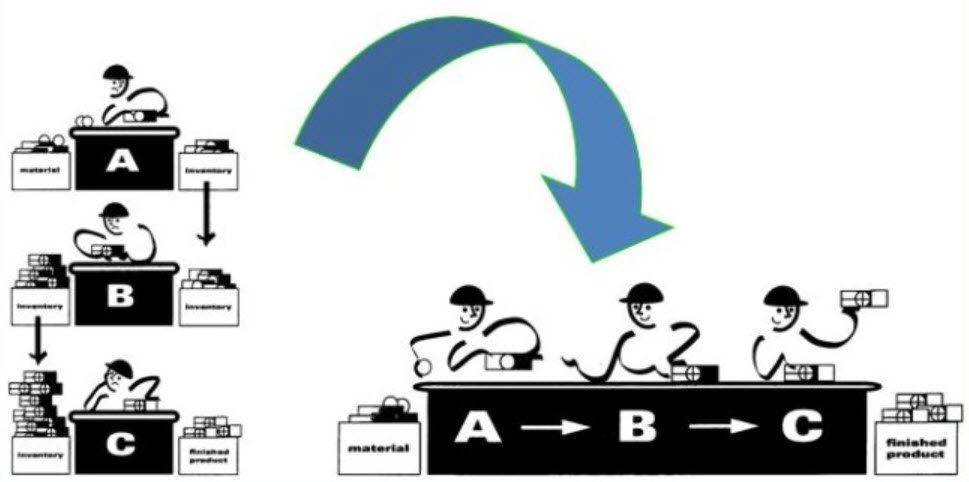

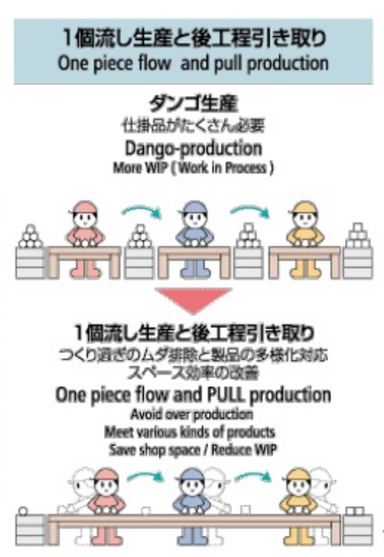

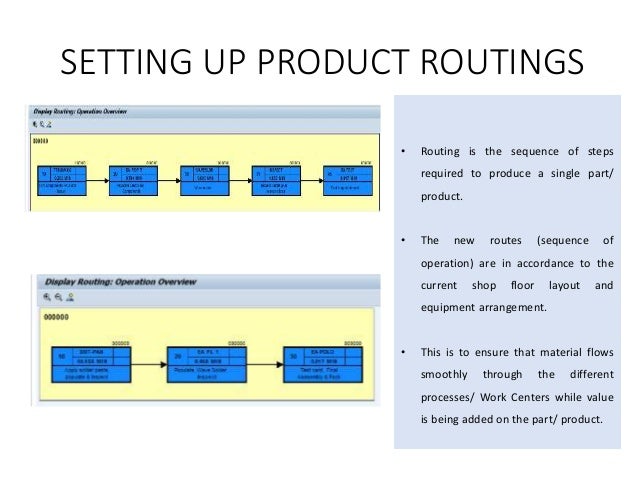

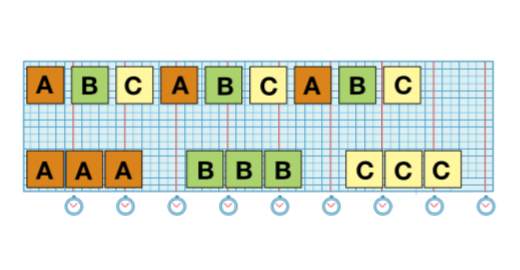

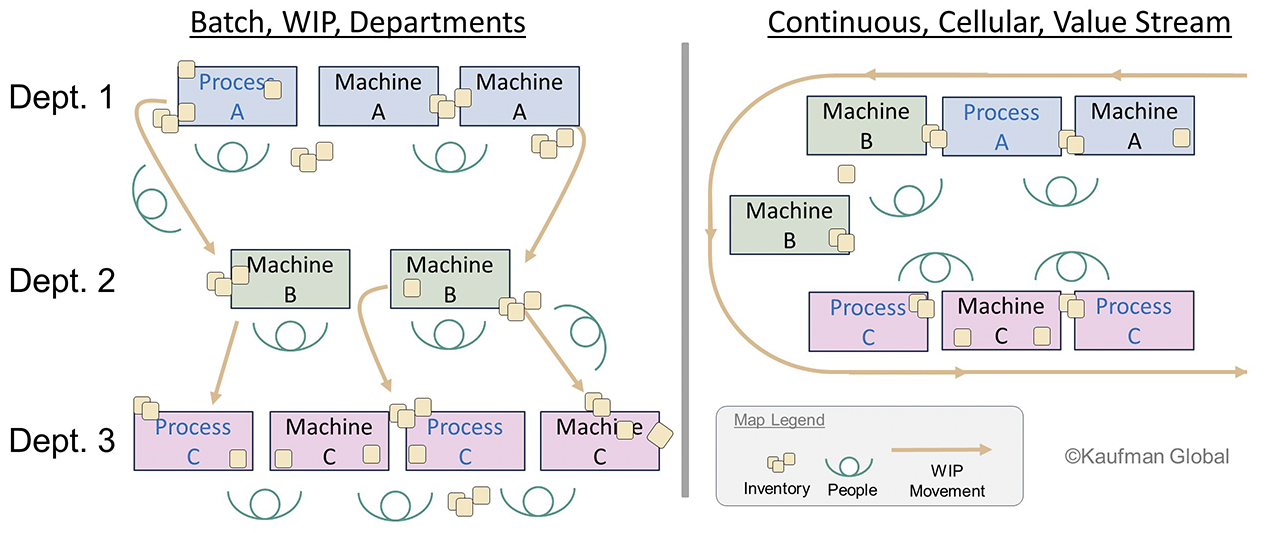

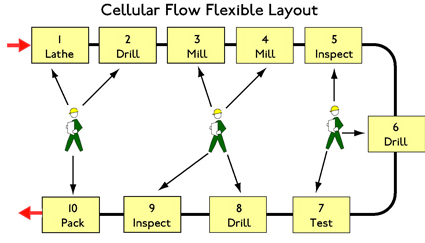

Continually move closer to the ideal state Activity Batch Processing vs Continuous Flow Processing The human mind likes batches!#Simulation of one piece flow vs batch production basics for starters #lean #kaizen #onepieceflow #flow #ci #cip #visual #continuousimprovement by Liked by Károly Klacskó Our new WEBSITE has launched!!→ One Piece Flow is moving one workpiece at a time between a work station within a cell or shop → In opposite conditions, we might process an entire batch or lot at each station before moving it to the next station → In simple language, it means that the parts are moved through operations from station to station with no workinprocess (WIP) at

One Piece Flow Benefits Explained By Gemba Academy Leanvlog

Lean Management Value Stream Mapping Vsm Transformation Innovation

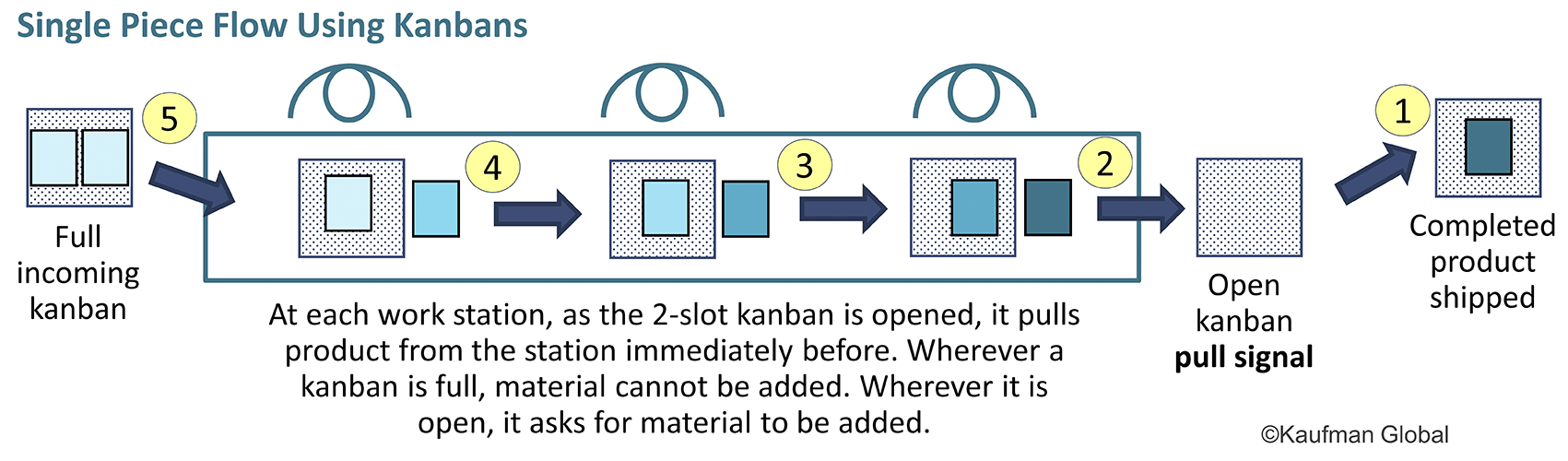

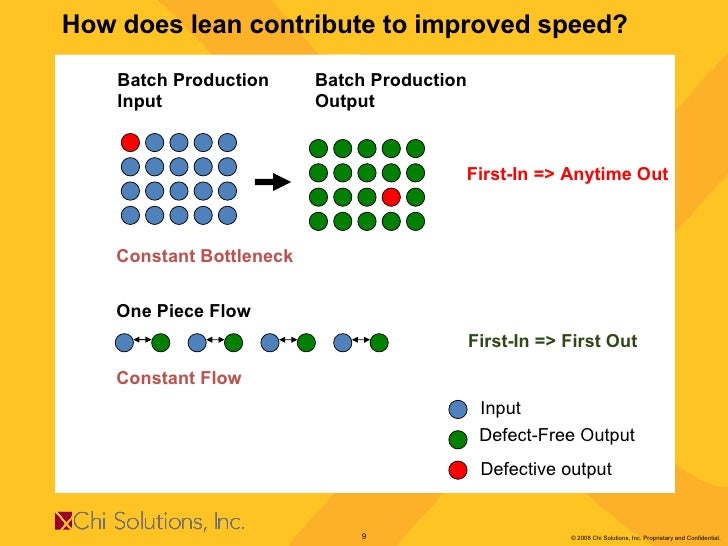

#Simulation of one piece flow vs batch production basics for starters #lean #kaizen #onepieceflow #flow #ci #cip #visual #continuousimprovement by Liked by Yasantha Hewage Join now to see all activity Experience IE MAS Linea Aqua Jan 14 Present 7 years 5 months View Yasantha's full profileThere's no inventory to build up between operations, so is there a benefit? In this context continuous flow refers to the continuous movement of cars from one stage to the next many cross functional teams working together on one car at a time One of the many differences between batch processing and continuous flow is the amount of WIP (work in process) Batch process have a lot of WIP

One Piece Flow Youtube

One Piece Flow Vs Batch One Piece Flow Vs Mass Production One Piece Flow Lean Manufacturing Youtube

One Piece Flow – the beginning The beginnings of the One Piece Flow are in 1934, when Kiichiro Toyoda used this method at a foundry and engine production He used a concept of "confirming one, after the other", which aimed at saving time and eliminating mistakes as they were spotted midbatch before affecting the entire orderONE PIECE FLOW versus BATCH PRODUCTION Lean Manufacturing11 Dec 7#Simulation of one piece flow vs batch production basics for starters #lean #kaizen #onepieceflow #flow #ci #cip #visual #continuousimprovement by Liked by Geno Bologna TTM Stafford is growing!

Lean Thinking And Methods Cellular Manufacturing Lean Practices Epa Us Epa

Batch And Queue Vs One Piece Flow Quarter Activity Continuous Improvement Blog

#Simulation of one piece flow vs batch production basics for starters #lean #kaizen #onepieceflow #flow #ci #cip #visual #continuousimprovement by Liked by Ndumiso Manana @bathu_sa East London Store opening #16th StoreOne Piece Flow vs batch production This nonprofessionally recorded video helps to understand the advantages of onepieceflow vs batch production It is a convincing exercise that I have been using since 06 to show the benefits in speed of onepieceflow versus batch production It takes less then 30 minutes to do the excercise, 68 magnetsEither one piece at a time or a small batch at a time Once work on a product begins it never stops moving until it is a finished product As opposed to onepiece flow, batch

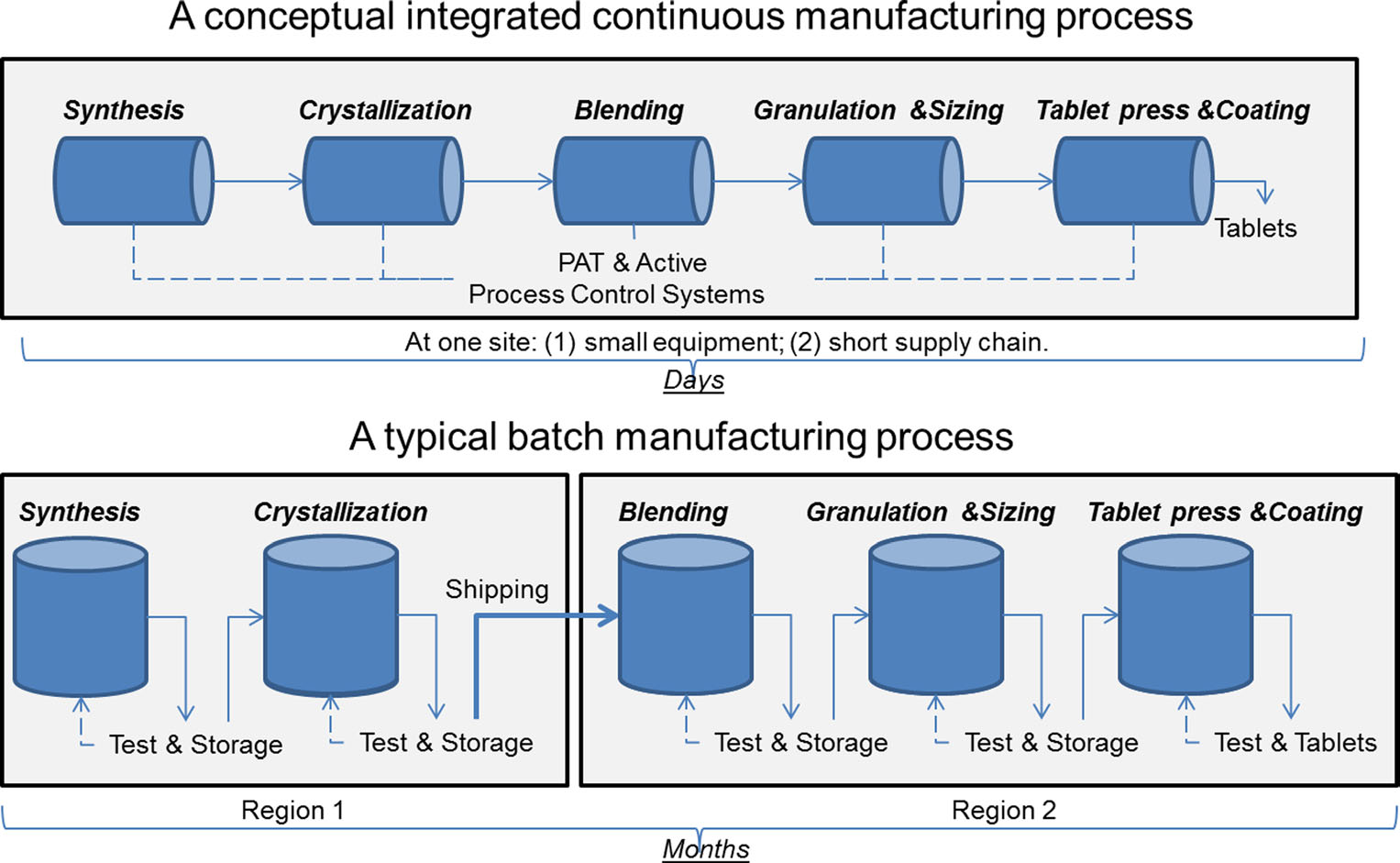

Modernizing The Way Drugs Are Made A Transition To Continuous Manufacturing Fda

Which Is More Productive Batch Working Or One Piece Flow Flowmotion

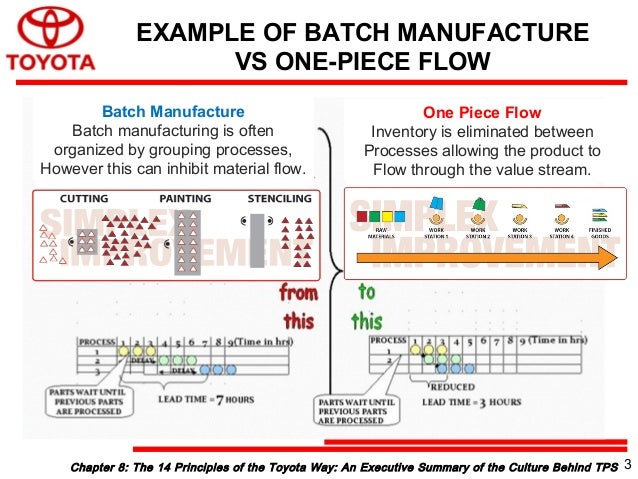

The difference between Toyota's OnePiece Flow Production method and the Batch method Hi, this is Mike Negami, Lean Sigma Black Belt Today's theme is Toyota's OnePiece Flow method, which is the opposite of the batch method One Piece Flow vs Batch production can be extremely quick and efficient Each aspect of the process is worked on, and then moves along to the next step with no wait time As a result, fast production means clients will have their finished product in a timely mannerSee how to transform slow and wasteful mass production into lean one piece flow in this simple and fun paper airplane simulationTIRED SEARCHING FOR THE BEST

Ask Art Why Do I Need To Switch From Batch To Flow

Batch Queue Vs Lean Continuous Flow

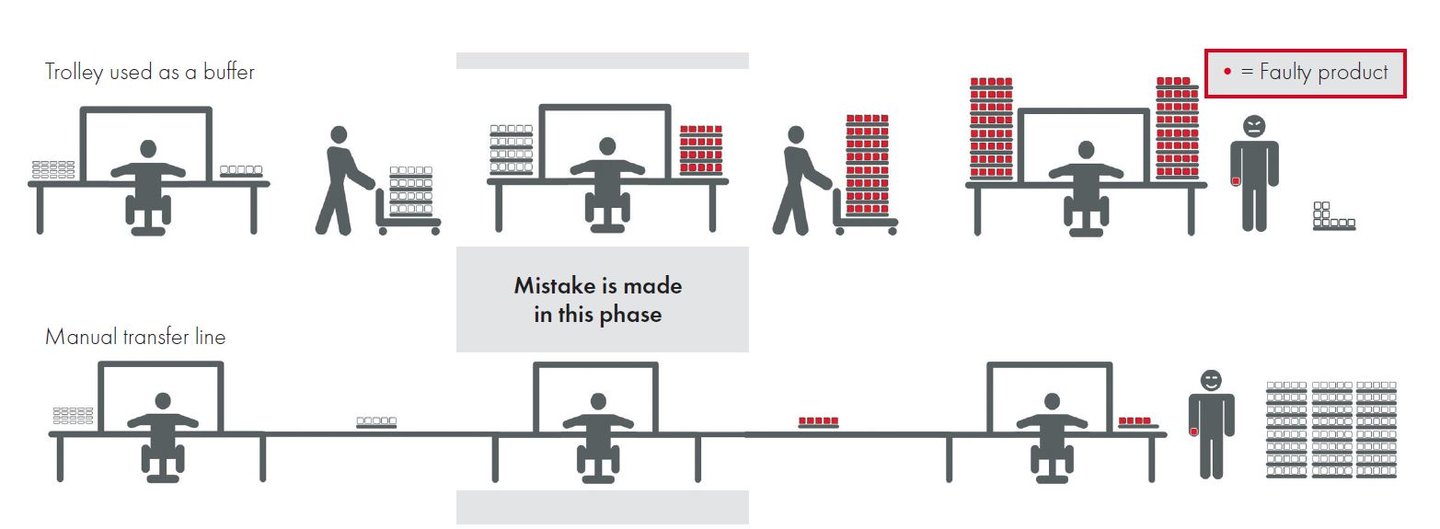

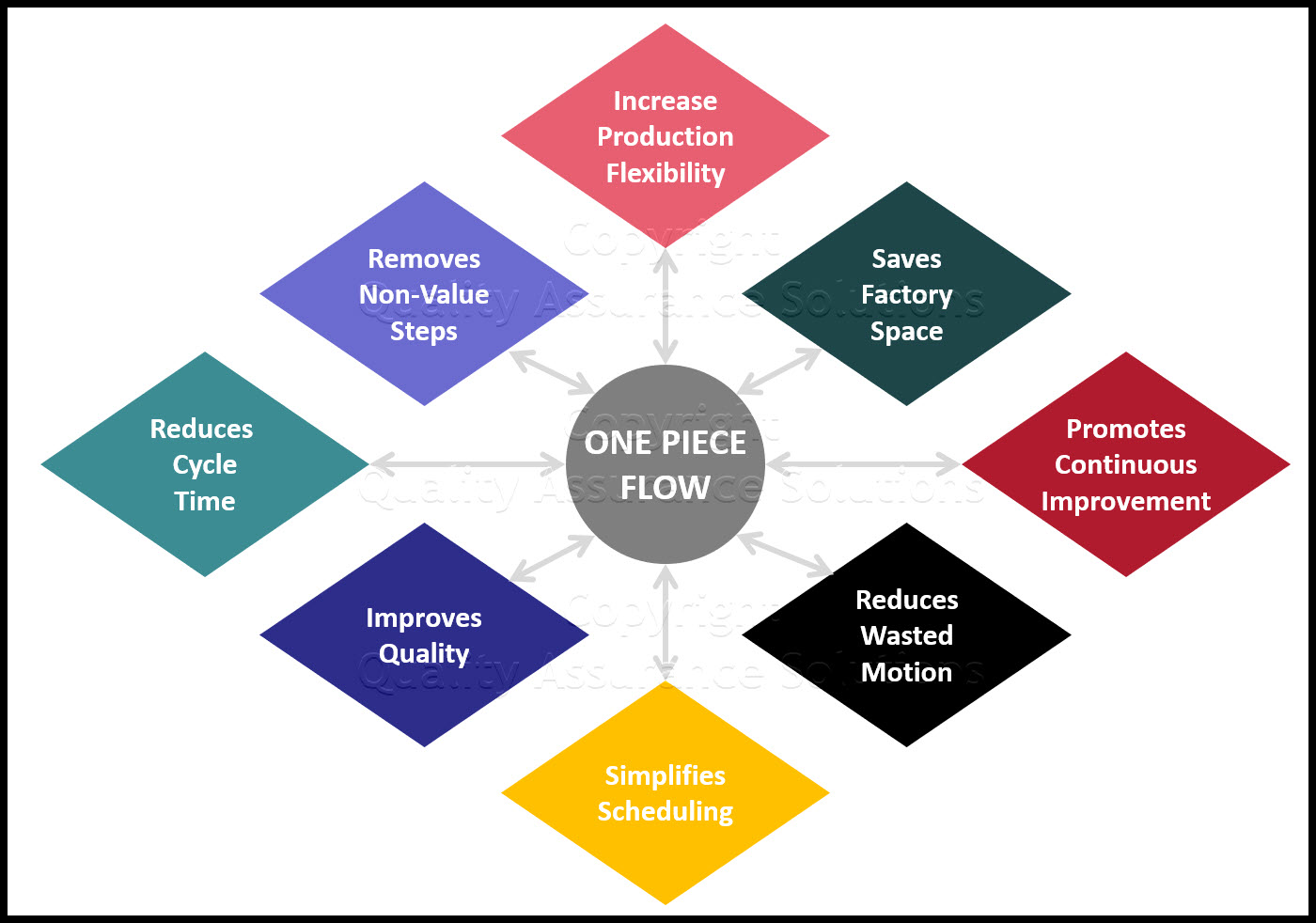

Why is important using OnePiece Flow in production?With fewer touches comes a reduction in workrelated injuries Improved quality and a reduction in defects – when an issue is detected in a onepiece flow system, it only affects the product in that step In contrast, a defect in a batch production line will affect an entire batch, or more, before itAbout Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

Azkurs Org

Flow Principle Lean Compass

What is One Piece Flow?#Simulation of one piece flow vs batch production basics for starters #lean #kaizen #onepieceflow #flow #ci #cip #visual #continuousimprovement by Liked by Huw Williams Double click if you see 😃 Always good when you have focus like this postAlso, batch production usually drives up inventory and lead time, unlike onepiece flow Little space is required for onepiece flow while batch production requires large space Onepiece flow lean assists in minimizing waste within the system of manufacturing of an organization Onepiece flow example is a software development project where

Achieving One Piece Flow

Toyota S One Piece Flow Production And Applying To Service Operations The Lean Farm Book Review 業務改善 Itコンサルティング Econoshift マイク根上

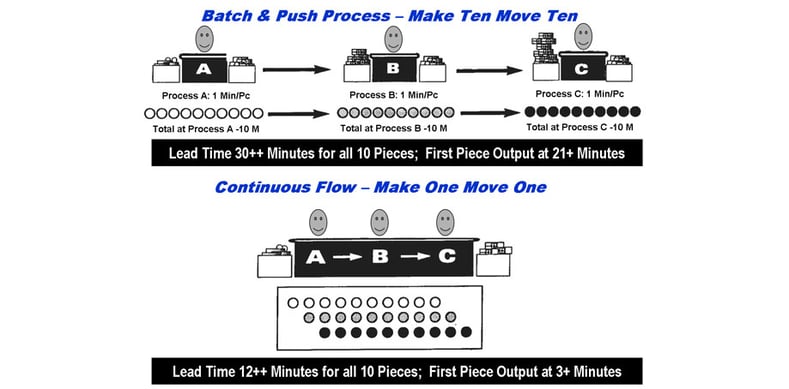

Also,the traditional batch processing is a push process in which the production happens based on the production schedule and not based on the pull of the customer Continuous flow Single Piece Flow The Single piece flow is the pull process in which the products are produced based on the customer requirementsThe concept has been around since at least the 1940's and it's called "One Piece Flow", or just Flow for short But don't be fooled by the simplicity of it Simple doesn't always mean easy!One way is to reduce batch sizesall the way to a size of one (singlepiece flow) if we can, which we usually do by moving operations physically close together so an operator can finish one piece and move it along to the next operation

Lean Manufacturing One Piece Flow Continuous Flow Animation Video Dailymotion

Comparison The Batch Production And One Piece Flow Activity Download Table

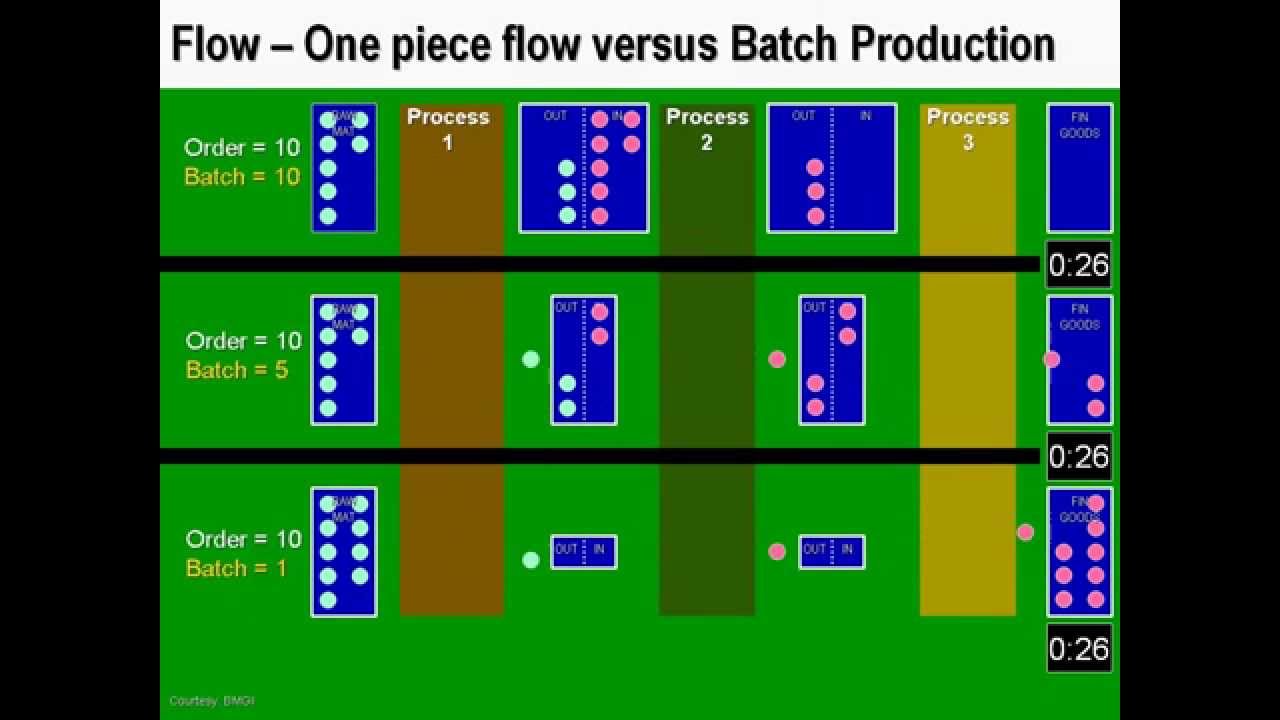

Simply speaking, the goal of onepiece flow is to have a single item or unit of product flow from process to process with no delays or bottlenecks in between The continuous flow approach contrasts with batch production and mass manufacturing In batch production, units are moved from process to process as a batchThis exercise will show which process is faster The faster process yields the benefits we discussed (recall benefits)The following illustration shows the impact of batch size reduction when comparing batchandqueue and onepiece flow Fig 3 Batch and queue flow Fig 4 Onepiece flow How we can see differences between these both flow systems is very enormous Onepiece

From Batch Production To One Piece Flow

Ppt Lean Production Overview Powerpoint Presentation Free Download Id

The six pack, or batch, is bundled at the end of production, not at every step Like batch manufacturing, all variables must be accounted for if this is the right manufacturing process for you Pros Quick One piece flow production is extremely quick and efficient#Simulation of one piece flow vs batch production basics for starters #lean #kaizen #onepieceflow #flow #ci #cip #visual #continuousimprovement by تمBatch Process vs One Piece Flow In batch processing, the part waits until all the other parts in the lot has been completed Then it moves to the next station, and again waits, and so on In one piece flow, however, the one piece does not have to wait It gets transformed into the finished product with minimum delay

One Piece Flow Batch Agar Business Consultancy

Benefits Of One Piece Flow And How It Is Implemented Latest Quality

Onepiece flow, can you get twopiece or threepiece?#Simulation of one piece flow vs batch production basics for starters #lean #kaizen #onepieceflow #flow #ci #cip #visual #continuousimprovement by Hi I like your article One thing I am interested in is how I can quantify the benefits so my business case is compelling I am thinking that I need to plot out our current batch process and establish a cost per function, ie batch WIP at each step, value for space (m2/$) per function, etc, then overlay a one piece flow process and use the difference to set the case

35 Lean Manufacturing Tools The Ultimate List

Tw8

#Simulation of one piece flow vs batch production basics for starters #lean #kaizen #onepieceflow #flow #ci #cip #visual #continuousimprovement by#Simulation of one piece flow vs batch production basics for starters #lean #kaizen #onepieceflow #flow #ci #cip #visual #continuousimprovement by Liked by Thembinkosi Sphamandla I will be graduating with my Bachelor of Technology in Mechanical Engineering (Cum Laude) from the Durban University of Technology 🎓🏆 Well#Simulation of one piece flow vs batch production basics for starters #lean #kaizen #onepieceflow #flow #ci #cip #visual #continuousimprovement by Shared by

Lean Management Simulation Of One Piece Flow Vs Batch

Five Heroes Of The Industry 4 0 In Spain All In The Opf One Piece Flow Arrizabalagauriarte Consulting

Singlepieceflow contrasts to traditional 'batchandqueue' production, which is the mass production practice of making large lots of a part and then sending the batch to wait in the queue before the next operation in the production process A 'push' production system is used, whereby a previous process manufactures as much as it can, without regard for the actual requirements OnePiece flow is one of the most important principles of lean manufacturing Onepiece flow means that parts are moved through operations from steptostep with no work in process in between;In this case, we've been taught since we were very young that "it's more efficient to work in batches" It requires many, many

Lean Lego Game

Lean Thinking And Methods Cellular Manufacturing Lean Practices Epa Us Epa

#Simulation of one piece flow vs batch production basics for starters #lean #kaizen #onepieceflow #flow #ci #cip #visual #continuousimprovement by Liked by3 rows OnePiece Flow is a lean manufacturing concept that is aimed to achieve a discrete flow of

One Piece Flow Versus Batch Production Lean Manufacturing Youtube

Lean Ppt2 A Rellicense Hrefhttp Creativecommons Orglicensesby4 0img

One Piece Flow Vs Batch Work Getting Our Heads Around Which Is Better Accuturn

One Piece Flow Work Cell Download Scientific Diagram

Batch Vs One Piece Flow Manufacturing Treston

Batch Vs One Piece Flow Manufacturing Treston

Batch Vs Flow Gif Gfycat

One Piece Flow Japanese Gemba Kaizen Web

1 Piece Flow Training

Lean Manufacturing One Piece Flow Vs Batch Flow

Single Piece Flow Why Mass Production Isn T The Most By Stefan Luyten Medium

One Piece Flow Vs Batch Production Youtube

One Piece Flow Vs Batch One Piece Flow Vs Mass Production One Piece Flow Lean Manufacturing Youtube

Flow One Piece Flow Vs Batch Production Video

One Piece Flow Vs Batch One Piece Flow Vs Mass Production One Piece Flow Lean Manufacturing Youtube

One Piece Flow Vs Batch Experiment Beanietech

Toyota S One Piece Flow Production And Applying To Service Operations The Lean Farm Book Review 業務改善 Itコンサルティング Econoshift マイク根上

Which Is More Productive Batch Working Or One Piece Flow Flowmotion

From Batch Production To One Piece Flow

One Piece Flow Manufacturing Creative Safety Supply

Onepieceflow Explore Facebook

Single Piece Flow Kaufman Global Just In Time One Piece Flow

E Learning Batch Vs One Piece Flow Production Training Dvd

Continuous

What Is One Piece Flow In The Production Process Breakout

Basics Of Continuous Flow Manufacturing Cfm With Example Sixsigmastats

Kanban Manufacturing Pull System Bin Systems And Conwip Kanban Lean Manufacturing Just In Time Manufacturing

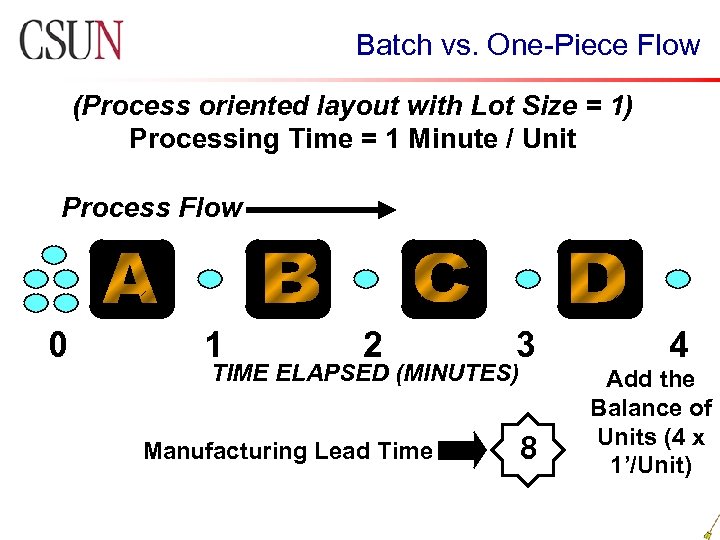

Csun Engineering Management Six Sigma Quality Engineering Week

Belajar Teknik Industri Continuous Flow One Piece Flow

Making Value Flow Archives Lean Photography Institute

One Piece Flow Reduce Batche Size To Streamline Throughput

Teaching Lean Construction I Pull Flow

Lean Production Control Pull Systems

Batch Production Kaufman Global Large Lot Production

Nwlean Feature Article

Batch V Lean 1 Piece Flow Training

Value Stream Mapping In Anatomic Pathology

Lean Manufacturing Tools

Difference Between Batch Processing And Single Piece Flow Hash Management Services Llp

Batch Production Vs One Piece Flow Youtube

Batch Vs One Piece Flow Manufacturing

Flow Production

One Piece Flow And Its Hidden Hazards Strategos

Achieving One Piece Flow

What Is One Piece Flow In The Production Process Breakout

Hand Offs Connection Are A Big Cause Of Waste In The Office Ppt Download

Lean Simulations Batch Vs One Piece Flow With Setup Manufacturing Video Dailymotion

One Piece Flow Vs Batching A Guide To Understanding How Continuous F

Benefits Of Single Piece Flow Production System

15 Essential Lean Manufacturing Tools And Principles Lean Smarts

How One Piece Flow Can Reduce Your Operations Time By 96 Process Street Checklist Workflow And Sop Software

Carl Starendal One Piece Flow Versus Batch Production Lean Manufacturing Facebook

Lean Cellular Manufacturing Processing Methods Layouts And Implementation

One Piece Flow Single Piece Flow Example

What Is One Piece Flow In The Production Process Breakout

One Piece Flow Iso Consultant In Kuwait

One Piece Flow Manufacturing Creative Safety Supply

Five Heroes Of The Industry 4 0 In Spain All In The Opf One Piece Flow Arrizabalagauriarte Consulting

Productivity Improvement Ppt Download

How One Piece Flow Can Reduce Your Operations Time By 96 Process Street Checklist Workflow And Sop Software

One Piece Flow

Image Result For One Piece Flow Vs Batch Production Back To School Principles Practices Pinterest Batch Production And School

10 Benefits Of One Piece Flow Gemba Academy

Make Your Process One Piece Flow Leanhill

One Piece Flow Vs Batch One Piece Flow Vs Mass Production One Piece Flow Lean Manufacturing Youtube

One Piece Flow Vs Batch One Piece Flow Vs Mass Production One Piece Flow Lean Manufacturing Youtube

One Piece Flow

Standard Business Roadmap Ppt Download

3

Devops And The Principle Of Flow Priyank Verma

Core Competency Capability Lean Culture Building Up

What Is One Piece Flow In The Production Process Breakout

Achieving One Piece Flow

Csun Engineering Management Six Sigma Quality Engineering Week

William Lancaster Sr Operational Excellence Manager Honeywell Linkedin

How One Piece Flow Can Reduce Your Operations Time By 96 Process Street Checklist Workflow And Sop Software

One Piece Flow Vs Batch Production Toyata Production System Tps

En Batch Vs One Piece Flow Airport Youtube

コメント

コメントを投稿